Coal

| I | INTRODUCTION |

Coal Miners

A coal train leaves a mine in Scranton, Pennsylvania, in 1919. United States President William Howard Taft created a federal Bureau of Mines with the objective of reducing mine accidents and fatalities.

CORBIS-BETTMANN

Coal, a combustible organic rock composed primarily of carbon, hydrogen, and oxygen. Coal is burned to produce energy and is used to manufacture steel. It is also an important source of chemicals used to make medicine, fertilizers, pesticides, and other products. Coal comes from ancient plants buried over millions of years in Earth’s crust, its outermost layer. Coal, petroleum, natural gas, and oil shale are all known as fossil fuels because they come from the remains of ancient life buried deep in the crust.

Coal is rich in hydrocarbons (compounds made up of the elements hydrogen and carbon). All life forms contain hydrocarbons, and in general, material that contains hydrocarbons is called organic material. Coal originally formed from ancient plants that died, decomposed, and were buried under layers of sediment during the Carboniferous Period, about 360 million to 290 million years ago. As more and more layers of sediment formed over this decomposed plant material, the overburden exerted increasing heat and weight on the organic matter. Over millions of years, these physical conditions caused coal to form from the carbon, hydrogen, oxygen, nitrogen, sulfur, and inorganic mineral compounds in the plant matter. The coal formed in layers known as seams.

Plant matter changes into coal in stages. In each successive stage, higher pressure and heat from the accumulating overburden increase the carbon content of the plant matter and drive out more of its moisture content. Scientists classify coal according to its fixed carbon content, or the amount of carbon the coal produces when heated under controlled conditions. Higher grades of coal have a higher fixed carbon content.

| II | MODERN USES OF COAL |

Eighty-six percent of the coal used in the United States is burned by electric power plants to produce electricity. When burned, coal generates energy in the form of heat. In a power plant that uses coal as fuel, this heat converts water into steam, which is pressurized to spin the shaft of a turbine. This spinning shaft drives a generator that converts the mechanical energy of the rotation into electric power (see Electric Motors and Generators; Steam Engine).

Coal is also used in the steel industry. The steel industry uses coal by first heating it and converting it into coke, a hard substance consisting of nearly pure carbon. The coke is combined with iron ore and limestone. Then the mixture is heated to produce iron (see Iron and Steel Industry). Other industries use different coal gases given off during the coke-forming process to make fertilizers, solvents, medicine, pesticides, and other products.

Fuel companies convert coal into easily transportable gas or liquid fuels (see Synthetic Fuels). Coal-based vapor fuels are produced through the process of gasification. Gasification may be accomplished either at the site of the coalmine or in processing plants. In processing plants, the coal is heated in the presence of steam and oxygen to produce synthesis gas, a mixture of carbon monoxide, hydrogen, and methane used directly as fuel or refined into cleaner-burning gas.

On-site gasification is accomplished by controlled, incomplete burning of an underground coal bed while adding air and steam. To do this, workers ignite the coal bed, pump air and steam underground into the burning coal, and then pump the resulting gases from the ground. Once the gases are withdrawn, they may be burned to produce heat or generate electricity. Or they may be used in synthetic gases to produce chemicals or to help create liquid fuels.

Liquefaction processes convert coal into a liquid fuel that has a composition similar to that of crude petroleum. Coal can be liquefied either by direct or indirect processes. However, because coal is a hydrogen-deficient hydrocarbon, any process used to convert coal to liquid or other alternative fuels must add hydrogen. Four general methods are used for liquefaction: (1) pyrolysis and hydrocarbonization, in which coal is heated in the absence of air or in a stream of hydrogen; (2) solvent extraction, in which coal hydrocarbons are selectively dissolved and hydrogen is added to produce the desired liquids; (3) catalytic liquefaction, in which hydrogenation takes place in the presence of a catalyst; and (4) indirect liquefaction, in which carbon monoxide and hydrogen are combined in the presence of a catalyst.

| III | COAL FORMATION |

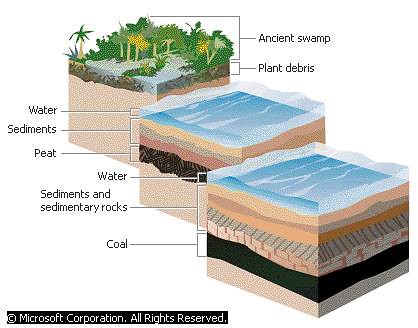

How Coal Forms

The coal we find today formed from generations of plants that died in ancient tropical swamps and accumulated on the swamp bottoms. The plant material first formed a compact organic material called peat. As layers of sediment gradually accumulated over the peat, the pressure and heat exerted by the thickening layers gradually drove out the moisture and increased the carbon content of the peat, forming coal.

© Microsoft Corporation. All Rights Reserved.

Cutting Peat

A worker cuts peat from lush peatland in Ireland. Peat is the first stage in the transformation of vegetation into coal. For hundreds of years, people have cut, dried, and burned it for heating and cooking. This compact, dark-brown material contains about one third less heating value than coal.

Farrell Grenan/Photo Researchers, Inc.

Before decayed plant material forms coal, the plant material forms a dark brown, compact organic material known as peat. Although peat will burn when dried, it has a low carbon and high moisture content relative to coal. Most of coal’s heating value comes from carbon, whereas inorganic materials, such as moisture and minerals, detract from its heating value. For this reason, peat is a less efficient fuel source than coal. Over time, as layers of sediment accumulate over the peat, this organic material forms lignite, the lowest grade of coal. As the thickening geologic overburden gradually drives moisture from the coal and increases its fixed carbon content, coal evolves from lignite into successively higher-graded coals: subbituminous coal, bituminous coal, and anthracite. Anthracite, the highest rank of coal, has nearly twice the heating value of lignite (see Heat).

Coal formation began during the Carboniferous Period (known as the first coal age), which spanned 360 million to 290 million years ago. Coal formation continued throughout the Permian, Triassic, Jurassic, Cretaceous, and Tertiary Periods (known collectively as the second coal age), which spanned 290 million to 1.6 million years ago. Coals formed during the first coal age are older, so they are generally located deeper in Earth’s crust. The greater heat and pressures at these depths produce higher-grade coals such as anthracite and bituminous coals. Conversely, coals formed during the second coal age under less intense heat and pressure are generally located at shallower depths. Consequently, these coals tend to be lower-grade subbituminous and lignite coals.

| IV | COMPONENTS OF COAL |

Coal contains organic (carbon-containing) compounds transformed from ancient plant material. The original plant material was composed of cellulose, the reinforcing material in plant cell walls; lignin, the substance that cements plant cells together; tannins, a class of compounds in leaves and stems; and other organic compounds, such as fats and waxes. In addition to carbon, these organic compounds contain hydrogen, oxygen, nitrogen, and sulfur. After a plant dies and begins to decay on a swamp bottom, hydrogen and oxygen (and smaller amounts of other elements) gradually dissociate from the plant matter, increasing its relative carbon content.

Coal also contains inorganic components, known as ash. Ash includes minerals such as pyrite and marcasite formed from metals that accumulated in the living tissues of the ancient plants. Quartz, clay, and other minerals are also added to coal deposits by wind and groundwater. Ash lowers the fixed carbon content of coal, decreasing its heating value.

| V | COAL DEPOSITS AND RESERVES |

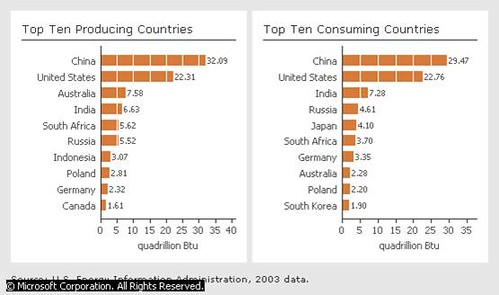

Coal Production and Consumption

A comparison of the top ten coal-producing countries and the top ten coal-consuming countries shows that China is both the leading producer and the leading consumer of coal. Coal is burned in power plants to produce electricity and in steel mills to make coke for the production of steel.

© Microsoft Corporation. All Rights Reserved.

Although coal deposits exist in nearly every region of the world, commercially significant coal resources occur only in Europe, Asia, Australia, and North America. Commercially significant coal deposits occur in sedimentary rock basins, typically sandwiched as layers called beds or seams between layers of sandstone and shale.

When experts develop estimates of the world’s coal supply, they distinguish between coal reserves and resources. Reserves are coal deposits that can be mined profitably with existing technology—that is, with current equipment and methods. Resources are an estimate of the world’s total coal deposits, regardless of whether the deposits are commercially accessible. Exploration geologists have found and mapped the world’s most extensive coal beds. At the beginning of 2001, global coal reserves were estimated at 984.2 billion metric tons, in which 1 metric ton equals 1,016 kg (2,240 lb). These reserves occurred in the following regions by order of importance: the Asia Pacific, including Australia, 29.7 percent; North America, 26.1 percent; Russia and the countries of the former Union of Soviet Socialist Republics (USSR), 23.4 percent; Europe, excluding the former USSR, 12.4 percent; Africa and the Middle East, 6.2 percent; and South and Central America, 2.2 percent.

Coal deposits in the United Kingdom, which led the world in coal production until the 20th century, extend throughout parts of England, Wales, and southern Scotland. Coalfields in western Europe underlie the Saar and Ruhr valleys in Germany, the Alsace region of France, and areas of Belgium. Coalfields in central Europe extend throughout parts of Poland, the Czech Republic, and Hungary. The most extensive and valuable coalfield in eastern Europe is the Donets Basin, between the Dnieper and Don rivers (in parts of Russia and Ukraine). Large coal deposits in Russia are being mined in the Kuznetsk Basin in southern Siberia. Coalfields underlying northwestern China are among the largest in the world. Mining of these fields began in the 20th century.

United States coal reserves are located in six major regions, three of which produce the majority of domestically mined coal. The most productive region in the United States is the Appalachian Basin, covering parts of Pennsylvania, West Virginia, Kentucky, Tennessee, Ohio, and Alabama. Large quantities of coal have also been produced by both the Illinois Basin—extending through Illinois, Indiana, and Kentucky—and the Western Interior Region—extending through Missouri, Kansas, and Oklahoma. Other commercially important U.S. coal regions include the Powder River Basin, underlying parts of Montana and Wyoming; the Green River Basin in Wyoming; the Uinta Basin, covering areas of Utah and Colorado; and the San Juan Basin, underlying parts of Utah, New Mexico and Colorado.

In 2002 estimates of total U.S. coal reserves were approximately 246 billion metric tons. At the beginning of the 21st century production amounted to about 980 million metric tons each year.

| VI | COAL MINING |

Coal mining is the removal of coal from the ground. The mining method employed to extract the coal depends on the following criteria: (1) seam thickness, (2) the overburden thickness, (3) the ease of removal of the overburden, (4) the ease with which a shaft can be sunk to reach the coal seam, (5) the amount of coal extracted relative to the amount that cannot be removed, and (6) the market demand for the coal.

The two types of mining methods are surface mining and underground mining. In surface mining the layers of rock or soil overlying a coal seam are first removed after which the coal is extracted from the exposed seam. In underground mining, a shaft is dug to reach the coal seam. Currently, underground mining accounts for approximately 60 percent of the world recovery of coal.

| A | Surface Mining |

Giant Coal Bucket

Strip miners often use extremely large buckets to level or move land. The buckets have sharp, slanted teeth on the front edge and are dragged along the surface of the ground by powerful machines. This bucket, used in the Big Muskie coal mine in Ohio, is the size of a small house.

UPI/THE BETTMANN ARCHIVE

Surface mining is used to reach coal reserves that are too shallow to be reached by other mining methods. Types of surface mining include open-pit mining, drift mining, slope mining, contour mining, and auger mining.

| A1 | Open-pit Mining |

In open-pit mining, or strip mining, earth-moving equipment is used to remove the rocky overburden and then huge mechanical shovels scoop coal up from the underlying deposit. The modern coal industry has developed some of the largest industrial equipment ever made, including shovels capable of holding 290 metric tons of coal.

To reach the coal, bulldozers clear the vegetation and soil. Depending on the hardness and depth of the exposed sedimentary rocks, these rocky layers may be shattered with explosives. To do this, workers drill blast holes into the overlying sedimentary rock, fill these holes with explosives, and then blast the overburden to fracture the rock. Once the broken rock is removed, coal is shoveled from the underlying deposit into giant earth-moving trucks for transport.

| A2 | Drift Mining |

Drift mining is used when a horizontal seam of coal emerges at the surface on the side of a hill or mountain, and the opening into the mine can be made directly into the coal seam. This type of mining is generally the easiest and most economical type because excavation through rock is not necessary. If coal is available in this manner, it is likely to be mined.

| A3 | Slope Mining |

Slope mining occurs when an inclined opening is used to tap the coal seam (or seams). A slope mine may follow the coal seam if the seam is inclined and exposed to the surface, or the slope may be driven through rock strata overlying the coal to reach a seam. Coal transportation from a slope mine can be accomplished by conveyor or by track haulage (using a trolley locomotive if the grade is not severe) or by pulling mine cars up the slope using an electric hoist and steel rope if the grade is steep. The most common practice is to use a belt conveyor.

| A4 | Contour Mining |

Contour mining occurs on hilly or mountainous terrain, where workers use excavation equipment to cut into the hillside along its contour to remove the overlying rock and then mine the coal. The depth to which workers must cut into the hillside depends on factors such as hill slope and coal bed thickness.

| A5 | Auger Mining |

Auger mining is frequently employed in open-pit mines where the thickness of the overburden is too great for open-pit mining to be cost-effective. Open-pit mining would require the lengthy and costly removal of the overburden, whereas auger mining is more efficient because it cuts through the overburden and removes the coal as it drills. In this technique, the miners drill a series of horizontal holes into the coal bed with a large auger (drill) powered by a diesel or gasoline engine. These augers are typically about 60 m (200 ft) long and 0.6 to 2.1 m (2 to 7 ft) in diameter. As these enormous drills bore into the coal seam, they discharge coal like a wood drill producing wood shavings. Additional auger lengths are added as the cutting head of the auger penetrates farther into the coal. Penetration continues until the cutting head drifts into the top or bottom of the coal seam, into a previous hole, or until the maximum torque (energy required to twist an object) of the auger is reached.

| A6 | Satellite Aids to Surface Mining |

In the late 1990s some coal mining enterprises used technologies such as the global positioning system (GPS) to help guide the positioning of mining equipment. Satellites operated by the United States Air Force Space Command and leased to companies for commercial use track the position of mining equipment against a map of a mine’s topography. This map uses colors to distinguish soil that should be excavated, soil that should remain in place, and areas that should be filled in. The equipment driver observes this visual information on a monitor while operating the equipment. Some coal mining enterprises have used GPS to increase mining efficiency up to 30 percent.

| B | Underground Mining |

Big Pit Mining Museum, Blaenafon

Coal mining was once the main industry of the Rhondda Valley in Great Britain. The Big Pit ("Pwll Mawr") coal mine ceased production in 1980 but its buildings and machinery were preserved and converted into a museum of mining. Visitors descend into the mine via the 90-m (300-ft) lift shaft to walk through underground roadways, air doors, stables (for pit ponies), and engine houses constructed by past generations of miners.

Spectrum Colour Library

Underground, or deep, mining occurs when coal is extracted from a seam without removal of the overlying strata. Miners build a shaft mine that enters the earth through a vertical opening and descends from the surface to the coal seam. In the mine, the coal is extracted from the seam by various methods, including conventional mining, continuous mining, longwall mining, and room-and-pillar mining.

| B1 | Conventional Mining |

Conventional mining, also called cyclic mining, involves a sequence of operations that proceed in the following order: (1) supporting the roof, (2) ventilation, (3) cutting, (4) drilling, (5) blasting, (6) coal removal, and (7) loading. First, miners make the roof above the seam safe and stable by timbering or by roof bolting, processes intended to prevent the roof from collapsing. At the same time, they create ventilation openings so that dangerous gases can escape and fresh air can reach the miners. Then one or more slots—a few centimeters wide and extending for several meters into the coal—are cut along the face of the coal seam, also known as the wall face, by a large, mobile cutting machine. The cut, or slot, provides easy access to the face and facilitates the breaking up of the coal, which is usually blasted from the seam by explosives known as permissible explosives. This type of explosive produces an almost flame-free explosion and markedly reduces the amount of noxious fumes in comparison with conventional explosives. The coal may then be transported by rubber-tired electric vehicles (shuttle cars) or by chain (or belt) conveyor systems.

| B2 | Continuous Mining |

Continuous mining involves the use of a single machine known as a continuous miner that breaks the coal mechanically and loads it for transport. This mobile machine has a series of metal-studded rotating drums that gouge coal from the face of the coal seam. One continuous miner can mechanically break apart about 1.8 metric tons of coal per hour. Roof support is then installed, ventilation is advanced, and the coalface is ready for the next cycle. The method used to transport the coal requires the installation of mobile belt conveyors.

| B3 | Longwall Mining |

The longwall mining system uses a remote-controlled self-advancing roof in which large blocks of coal are completely extracted in a continuous operation. Hydraulic or self-advancing jacks, known as chocks, support the roof at the immediate face as the coal is removed. As the face advances, the roof is allowed to collapse behind the remote-controlled, roof-building machinery. Miners then remove the fallen coal. Coal recovery is comparable to that attainable with the conventional or continuous mining systems.

| B4 | Room-and-Pillar Mining |

Room-and-pillar mining is a means of developing a coalface and, at the same time, retaining supports for the roof. With this technique, rooms are developed from large, parallel tunnels driven into the solid coal, and the intervening pillars of coal are used to support the roof. The percentage of coal recovered from a seam depends on the number and size of protective pillars of coal thought necessary to support the roof safely. Workers may remove some coal pillars just before closing the mine.

| VII | COAL MINING SAFETY |

Coalmines are hazardous operations. In the 20th century, more than 100,000 miners died working in coalmines. Many accidents were caused by the mine structure failing through roof collapse or rock bursts (coal pillars exploding from the weight of excessive overburden). Other dangers that miners face include toxic or explosive gases released as the coal is mined, dangerous coal dust, and fires. Fires result when flammable gases trapped in the coal, such as methane, are released during mining operations and accidentally ignited.

Provision of adequate ventilation is an essential safety feature of underground coal mining. Not all of this ventilation is required to enable miners to work in comfort. Most of it is required to dilute the harmful gases, frequently termed damps, produced during mining operations.

| A | Mine Failure |

In room-and-pillar mines deep underground, the extreme weight of the overlying rock can break the pillars down, either gradually or in a violent collapse. If the mine roof or floor consists of softer material such as clay, the massive weight of the overburden can slowly push the pillars into the floor or ceiling, endangering the stability of the mine. When the mine roof and floor consist of particularly hard rock, massive overhead weight can overload the pillars, sometimes causing a spontaneous collapse or rock burst.

| B | Gases |

Because coal and natural gas form by similar natural processes, methane (a principal component of natural gas) is often trapped inside coal deposits. Gases trapped in deeper coal beds have a harder time escaping. Consequently, high-grade coals, which are typically buried deeper than low-grade coals, often contain more methane in the pores and fractures of the deposit. As coalminers saw or blast into a coal deposit, they can release these methane pockets, which may explode spontaneously, often with deadly results. Miners use a technique called methane drainage to reduce dangerous releases of methane. Before mining machinery cuts into the wall face, holes are drilled into the coal and methane is drawn out and piped to the surface.

Coalminers also risk being exposed to other deadly gases, including carbon monoxide, a poisonous by-product of partially burned coal. Carbon monoxide is deadly in quantities as little as 1 percent. It is especially prevalent in underground mines after a methane explosion. In the early 1800s, after a gas explosion, coalminers used canaries to test for carbon monoxide. If the canary died, the miners increased ventilation in the mine to remove the carbon monoxide. The miners then conducted the same test with another canary and repeated the process until a bird survived. Miners also tested for carbon monoxide and methane with a small flame. If the flame’s size increased, methane was present in the air; if the flame went out, carbon monoxide was present.

Other dangerous gases locked inside coal deposits include hydrogen sulfide, a poisonous, colorless gas with an odor of rotten eggs, and carbon dioxide, a colorless, odorless gas. To prevent injury from inhaling these gases, underground coalmines must be sufficiently ventilated. To do this fresh air is continuously pumped through ventilation holes to push out or dilute dangerous gases and provide air for miners to breathe.

| C | Coal Dust |

As coal is blasted, shredded, and hauled in a mine, large amounts of coal and silica dust are produced. Coal dust is extremely flammable, and if ignited it can be more violently explosive than methane. Miners can reduce the buildup of coal dust by injecting pressurized water into coal beds before the coal is blasted or cut, by spraying water at all points where dust is likely to be formed, and by installing dust extraction units at strategic points.

Miners who inhale coal dust over a prolonged period can damage their lung tissue. Often, these miners develop spots, lumps, or fibrous growths in their lungs, a condition known as black lung disease, a type of pneumoconiosis. Furthermore, black lung disease can develop into other, often fatal illnesses, including heart disease, emphysema, and cancer. To protect miners from black lung, many mines are equipped with coal-dust filtering units. Miners who operate drilling, cutting, or loading machinery should wear masks at all times.

| D | Fires |

Coalmine fires can be triggered during routine mining operations. For example, sparks generated by mining equipment can ignite explosive gases, coal dust, and even the coal bed itself. Because coal beds provide an almost inexhaustible fuel source, once a coal seam is ignited, it can be extremely difficult to extinguish. The intense heat generated by burning coal can rupture the overlying rock strata, sometimes causing the roof to collapse. Uncontrollable fires in some coal deposits have continued burning for years, posing a danger to local communities.

Regulations to prevent and control mine fires have been enacted in the United States and other countries. The U.S. regulations require mining companies to install fire-fighting equipment and automatic fire-suppression systems in mines. Internal-combustion engines, which power mining machinery, such as trucks, shuttles, tractors, and scoops, reach high temperatures that can pose a fire hazard. As a result, this equipment must be designed and operated according to the guidelines of the U.S. Mine Safety and Health Administration.

| VIII | POSTMINING PROCESSES |

Once the coal has been mined, it must be prepared for commercial use and then either stored or transported.

| A | Coal Preparation |

As-mined coal, also known as run-of-mine coal, often contains unwanted impurities such as rock and dirt and comes in a mixture of different-sized fragments. Thus, another sequence of processes is necessary to make the coal consistent in quality and suitable for selling. These processes are called coal preparation or coal cleaning. Effective preparation of coal prior to combustion improves the homogeneity of the coal supplied, reduces transport costs, improves the burning efficiency, and produces fewer pollutants.

Coal preparation is the stage in coal production when the run-of-mine coal is processed into a range of clean, graded, and uniform coal products suitable for the commercial market, mostly power plants. In some cases, the run-of-mine coal is of such quality that it meets the user’s specifications without the need for preparation, in which case the coal would merely be crushed and put through a large sievelike device to deliver the specified product.

A number of physical separation technologies are used in cleaning and preparing coal. After the raw run-of-mine coal is crushed, it is separated into various-sized fragments for optimum treatment. Larger material— lumps of coal about 10 to 150 mm (0.4 to 6 in) in length—is usually treated using a technology known as dense-medium separation. The dense medium is usually a liquid with a density just slightly greater than that of the coal. The coal can then be separated from other impurities, such as rock, by being floated in a tank containing the high-density liquid, which is usually a suspension of finely ground magnetite. Because the coal is lighter, it floats and is separated off, while heavier rock and other impurities sink and are removed as waste. Any magnetite mixed with the coal is separated using water sprays and is then recovered, using magnetic drums, and recycled.

The smaller-sized fragments are treated in a variety of ways. In the froth flotation method, coal particles are removed in a froth produced by blowing air into a water bath containing a chemical reagent (substance that takes part in a chemical reaction with another substance). The bubbles attract the coal but not the waste and are skimmed off to recover the smaller-sized fragments. After treatment, the smaller-sized fragments are screened and either dewatered or dried, and then recombined before going through final sampling and quality control procedures. Recombination also enables customers to selectively purchase different grades of coal. More expensive, higher quality supplies can be carefully mixed with lower quality coals to produce an average blend suited to the needs of commercial customers, such as power plants.

| A1 | Transport and Storage |

Once the coal has been extracted, it is moved from the mine to the power plant or other place of use or it is stored. Over short distances coal is usually transported by conveyor or truck. For long distances trains, barges, ships, or pipelines are used. Preventive measures are taken at every stage during transport and storage to reduce potential environmental impacts. Dust can be controlled by using water sprays, compacting the coal, and enclosing the stockpiles. Sealed systems can be used to move the coal from the stockpiles to the combustion plant. Well-designed coal-storage facilities can limit the problem of contaminated water run-off. All water is carefully treated before reuse or disposal.

| IX | ENVIRONMENTAL ISSUES |

Because significant volumes of earth must be displaced to mine coal, coalmines and the resulting rock waste can harm the environment. Furthermore, burning coal releases environmentally harmful chemical compounds into the air.

| A | Mining and Mining Waste |

Coal Strip Mine

This excavated area, which borders farmland, has been strip mined for coal. Unless the strip mine is filled and revegetated, surface water runoff from the mined area can flush sediments and sulfur-bearing compounds (acid drainage) into nearby streams and rivers, endangering plant and wildlife communities.

Charles E. Rotkin/Corbis

Surface mining has resulted in a great deal of damage to the landscape. Many surface mines have removed acres of vegetation and altered topographic features, such as hills and valleys, leaving soil exposed for erosion. Longwall mining, which allows the mine to collapse, results in widespread land subsidence, or sinking. Coal and rock waste, often dumped indiscriminately during surface and underground mining processes, weathers rapidly, producing acid drainage. Acid drainage contains sulfur-bearing compounds that combine with oxygen in water vapor to form sulfuric acid. In addition, weathering of coalmine waste can produce alkaline compounds, heavy metals, and sediments. Acid drainage, alkaline compounds, heavy metals, and sediment leached from mine waste into groundwater or washed away by rainwater can pollute streams, rivers, and lakes.

Today, enterprises in many countries must secure government permits before mining for coal. In the United States, mining companies must submit plans detailing proposed methods for blasting, road construction, land reclamation, and waste disposal. New land reclamation methods, driven by stringent laws and regulations, require coal mining companies to restore strip-mined landscapes to nearly premined conditions.

| B | Burning Coal |

The burning of coal produces environmentally harmful emissions. Some gases produced from burning coal, such as carbon dioxide, are known as greenhouse gases because they trap the Earth’s heat like the roof of a greenhouse and may contribute to global warming. Other emissions from coal combustion can lead to air and water pollution.

| B1 | Greenhouse Effect |

Earth absorbs much of the heat energy radiated from the Sun. The planet then reradiates this heat back into the atmosphere. Carbon dioxide and some other gases that are naturally present in the atmosphere prevent much of the heat from escaping back into space, maintaining Earth at a temperature that can support life. These gases are known as greenhouse gases because they trap the Sun’s heat in much the same way as the glass roof of a botanical greenhouse (see Greenhouse Effect). However, the immense quantity of fossil fuels burned during the world’s rapid industrialization over the last 200 years has raised levels of carbon dioxide in the atmosphere by about 28 percent. This dramatic increase in atmospheric carbon dioxide, coupled with continuing depletion of the world’s forests, which absorb carbon dioxide, has led many scientists to predict a heating of the atmosphere on a global scale. Such a global warming could disrupt weather patterns, cause the polar ice caps to melt, and possibly lead to other environmental problems.

Today, many industrial countries are working to reduce emissions of greenhouse gases. One proposal is to establish a system requiring companies that create greenhouse gases to pay to emit carbon dioxide above a specified level. This payment could take several forms, including (1) purchasing the rights to pollute from a company with carbon dioxide emissions below the specified level; (2) purchasing forests, which absorb carbon dioxide, and keeping them from being developed; or (3) paying to upgrade a plant in a developing country, thus lowering that plant’s carbon dioxide emissions.

| B2 | Acid Rain |

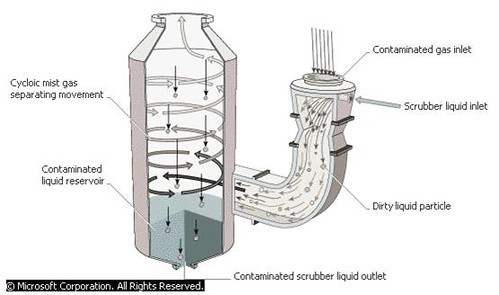

Anatomy of an Air Scrubber

A venturi air scrubber removes polluting particles from gas emissions by spraying a scrubber liquid directly into the emissions. The scrubber liquid surrounds the dirty particles, which are carried with the gas emissions into the separator cylinder. As the gas cycles upward through the cylinder, the liquid-covered particles drop from the gas into the contaminated liquid reservoir.

© Microsoft Corporation. All Rights Reserved.

The U.S. Clean Air Act, implemented in 1970 and revised in 1970 and 1990, is the federal law regulating air pollution in the United States. This legislation has significantly reduced emissions of sulfur oxides, known as acid gases (see Air Pollution). For example, the Clean Air Act requires facilities such as coal-burning power plants to burn low-sulfur coal. High-grade coals (coals with a higher heating value) generally contain more sulfur than low-grade coals such as lignite and subbituminous coal. Therefore, certain processes have been developed to remove sulfur-bearing compounds from high-grade coal prior to burning. The Clean Air Act also requires use of pollution-trapping equipment such as air scrubbers (devices installed inside plant smokestacks to remove sulfur dioxide from coal emissions). In addition, revisions to the Clean Air Act in 1990 established a system that allows coal-burning power plants to buy and sell sulfur emission permits with one another. This system tries to establish a financial incentive to lower sulfur emissions by rewarding power plants that reduce emissions below federal levels. Power plants that cut their sulfur emissions below the permitted levels can sell permits to burn coal to companies that exceed federal levels. Companies that reduce emissions reap financial rewards while polluters must pay an extra cost to pollute.

| B3 | Fly Ash |

The burning of coal releases ashes known as fly ash into the atmosphere. Fly ash contains toxic metals such as arsenic and cadmium. In the United States the Clean Air Act requires that fly ash be removed from coal emissions. As a result, antipollution devices such as air scrubbers, baghouses, and electrostatic precipitators are used to trap these pollutants. Baghouses work like giant vacuum cleaners, drawing coal emissions through giant fabric bags that trap the fly ash inside. Electrostatic precipitators use discharge electrodes (electrically charged parts of an electric circuit) to trap ash particles. In an electrostatic precipitator the electrodes are located between long, positively charged collection plates. As the fly ash passes between these collection plates, the discharge electrodes give each particle a negative charge. These negatively charged particles are then attracted to and held by the positively charged collection plates.

| X | CLEAN COAL TECHNOLOGY |

Since 1986 the United States government and private industry have been working together to develop cleaner and more efficient ways to harness the energy in coal. This joint effort, known as the Clean Coal Technology Demonstration Program, includes several technologies, such as fluidized bed coal combustion, furnace sorbent injection, and advanced flue-gas desulfurization.

Fluidized bed coal combustion burns coal in a limestone bed that transfers heat to water, generating steam. This steam is pressurized and used to turn a turbine shaft, which subsequently drives an electric generator. The limestone absorbs sulfur dioxide emitted by the coal, thus reducing the amount of acid gases released during combustion.

A process called furnace sorbent injection removes acid gas from coal emissions at less cost than expensive scrubbers. A sorbent is a highly absorbent material, such as powdered limestone. It is injected into furnaces, where the powdered limestone reacts with the acid gases emitted by the burning coal. The used powder is siphoned away through the furnace outtake and is captured (with fly ash) in a baghouse or electrostatic precipitator.

A process called advanced flue-gas desulfurization also removes acid gas from burning coal without expensive scrubbers. Emissions from burning coal are piped into a container called an absorber, where the acid gases react with an absorbing solution (such as a mixture of lime, water, and oxygen). This reaction forms gypsum, a soft white mineral valuable as an ingredient in cement.

| XI | HISTORY OF COAL USE |

Early humans used wood, straw, and dried dung for fuel. One of the earliest known references to coal was made by Greek philosopher and scientist Aristotle, who referred to charcoallike rock found in Thrace (a region on the northeastern shore of the Aegean Sea) and in northeastern Italy. Although authentic records are unavailable, historians believe coal was first used commercially in China. Reports indicate the Fu-shun mine in northeastern China provided coal for smelting copper and for casting coins around 1000 bc.

Coal cinders found among Roman ruins in England suggest that the Romans harnessed energy from coal before ad 400. The written records of the monk Reinier of Liège from the early 13th century describe workers mining black earth in Europe. Blacksmiths used this black earth as fuel for metalworking. Other historical records contain numerous references to coal mining in England, in Scotland, and in continental Europe throughout the 13th century.

In the early 18th century the demand for coal escalated when English iron founders John Wilkinson and Abraham Darby used coal, in the form of coke, to manufacture iron. An almost constant demand for coal was created by metallurgical and engineering developments, most notably the invention of the coal-burning steam engine by Scottish mechanical engineer James Watt in 1769.

Until the American Revolution (1775-1783), most of the coal consumed by the American colonies was imported from England or Nova Scotia. Wartime shortages and the need to manufacture munitions spurred the formation of small American coal-mining companies that mined Virginia’s Appalachian bituminous field and other deposits. By the early 1830s U.S. mining companies had emerged throughout the Appalachian region and along the Ohio, Illinois, and Mississippi rivers. The construction of the first practical locomotive in 1804 in England by British engineer Richard Trevithick sparked a tremendous demand for coal. The growth of the railroad industry and the subsequent rise of the steel industry in the 1800s spurred enormous growth in the coal industry in the United States and Europe.

The widespread use of petroleum as a fuel before, during, and after World War I (1914-1918) eventually reduced the demand for coal. The change from coal to oil as fuel in warships (particularly in the United States and British navies) in the early 1900s, the switch in the railway industry to diesel-electric locomotive engines in the 1940s and 1950s, and increasing use of natural gas as a heating fuel all contributed to a decline in coal production. In the 1980s and 1990s, petroleum continued to supplant coal in industry and was increasingly used in oil-fired power plants. Still, electric utilities continued to burn large amounts of coal to produce electricity.

Contributed By:

James Speight

Microsoft ® Encarta ® 2007. © 1993-2006 Microsoft Corporation. All rights reserved.

2 komentar:

I like to read your blog, this the fist... so next .. permit read again.. smile for you

http://baganbatublog.blogspot.com/

I like to read this article why because you provided more useful information about coal which contain advantages and dis-advantages.Great work

Underground Coal Gasification

Posting Komentar